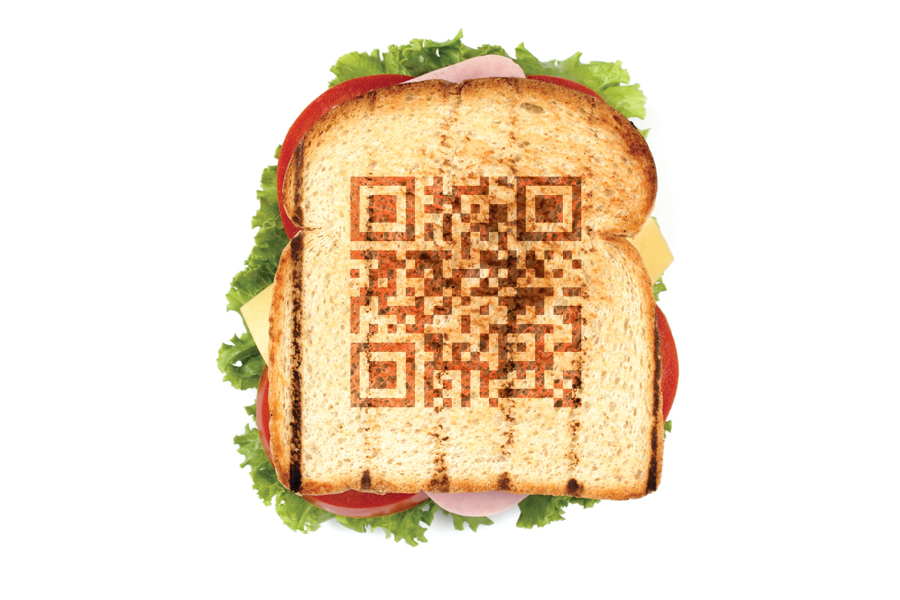

The future of the sandwich sector is here – and it’s primed to change the way we do business.

CHANGING TIMES

While the Digital Sandwich sounds like something from a Blade Runner sequel, it has the potential to completely disrupt the food industry. The aim is to deliver a national and open demonstrator of a digitalised supply chain, with sandwich manufacturing the test case – in simpler terms, Unit Level Traceability.

A UK government-backed consortium of leading food manufacturer Raynor Foods, technology specialists and academics launched the Digital Sandwich in April 2023, following a development project of two-and-a-half years. The platform, which received multi-million-pound investment from Innovate UK, has been developed to connect primary production and supply chains to retail, to provide traceability and provenance of ingredients – while increasing manufacturing productivity, improving processes and reducing waste across the supply chain.

The consortium behind the platform includes IMS Evolve, a leading UK IoT company; Raynor Foods, a leading UK sandwich supplier; University of Lincoln, University of Exeter, Digital Catapult, Sweetbridge, Inc., Crosspay, NetFoundry, INDUSTRIA Technology and R3, as well as supporting partners Kinesis Telematics Limited NESIS and Anser Coding Inc.

A QUESTION OF TRANSPARENCY

At the heartbeat of Digital Sandwich is Tom Hollands, innovation and technical director at Raynor Foods. Five years ago, in an article entitled Blockchain or Bust for the Food Industry, he wrote about how the highly complex global food supply chain lacked transparency and trust – and that scaling data was critical in chains with multiple exchange partners.

“This is very disruptive technology and a massive opportunity,” said Hollands. “Anyone can benefit from digital traceability within their factory – and it’s only the leaner and more efficient businesses that will ultimately prosper. Effectively, this is the forerunner to sustainable food systems; being able to connect, sharing valuable data up and down stream, delivering a level of assurance, transparency and authenticity that hasn’t been possible previously.”

The fully integrated digital platform fuses multiple industrial digital tech (IDTs; Blockchain, AI, IoT, Finance) into a single stack, operating within a standard business enterprise resource planning (ERP). But it’s the versatility that makes it so ground-breaking.

“The platform has different modules, but there is no monopoly of the tech,” continued Hollands. “People can be flipped in and out of Digital Sandwich, as it’s a platform made up of multiple components. The important aspect is that there are lots of different levels. Unit Level Traceability can track an ingredient all the way from the point where it leaves the supplier, comes in through goods, goes into storage, processing, and onto the production line and into the pack. Provenance, temperature, delivery records and food safety data all get written up to the blockchain. There is one source of truth.”

BIG DEAL

According to the Cold Chain Federation, the UK alone has nearly 41 million cubic metres of cold storage, equivalent to 35 Wembley Stadiums. It reports a 183% increase in wholesale energy costs for the cold chain sector during 2022, while it is estimated the UK generated over 9.5 million tons of food waste in 2021. With the UK sandwich industry alone worth an estimated £5.6bn, employing over 300,000 people across the country and growing at over 4% each year, digitalised cold chain processes that can significantly decrease food waste and improve shelf life – while also reducing overall energy consumption and cost of asset ownership – have the potential to transform our industry.

“The ability to use advanced technologies to irrefutably track ingredients in food, from primary production to retail, is going to bring one of the world’s most sophisticated supply chains into the digital age,” explained Edward Porter, director of IoT Solutions at retail technology experts, and consortium leaders, IMS Evolve. “We are delighted to have been involved in the Digital Sandwich project as the lead partners in a consortium that has the potential to completely digitally transform almost any complex supply chain system.”

“It demonstrates an impressive use case of this technology in the food retail supply chain, but the potential application spans across a wide range of different supply chain-dependent sectors in the UK and beyond, and that makes it really exciting,” said Lord Wei, a member of the House of Lords involved in the consortium via one of its members, Sweetbridge.

Following the project’s completion, the consortium will look to introduce and expand the solution across the food supply chain, establishing new use cases that leverage the technology’s flexibility to allow it to be used across other chains, possibly including the NHS or pharmaceuticals.

“We are delighted to be able to utilise this cutting-edge technology to further improve the way that we procure and monitor ingredients, manufacture sandwiches and deliver excellence for consumers and customers,” said Hollands. “We have absolute proof of concept with all the bits of kit working with each other.Getting to the final commercial product will take a bit longer, but we are excited about this technology.”